The Honda GX160 parts manual is an essential resource for understanding and maintaining your engine. It provides detailed diagrams, component lists, and repair guidelines to ensure optimal performance and longevity. By following the manual, users can identify parts, perform routine maintenance, and troubleshoot common issues effectively. This comprehensive guide is designed to help users operate and service their GX160 engine safely and efficiently, ensuring reliable operation for years to come.

Overview of the Honda GX160 Engine

The Honda GX160 is a reliable 4-stroke, single-cylinder engine known for its durability and fuel efficiency. Featuring a cast iron sleeve and a 3.1L fuel tank, it delivers consistent power for various applications. Designed for both residential and commercial use, the GX160 is commonly used in power equipment and small vehicles. Its compact design and robust construction make it a popular choice for generators, pressure washers, and go-karts. The engine’s performance and longevity depend on proper maintenance, as outlined in the parts manual, ensuring safe and efficient operation across diverse scenarios.

Importance of the Parts Manual for Maintenance and Repair

The Honda GX160 parts manual is crucial for effective maintenance and repair. It provides detailed diagrams and descriptions to help identify and replace parts accurately. By following the manual, users can perform routine maintenance, troubleshoot issues, and ensure proper repairs. This reduces the risk of engine damage and extends its lifespan. The manual’s guidance also helps prevent costly mistakes, making it an indispensable tool for both novice and experienced users. Regular maintenance, as outlined, ensures optimal performance, safety, and reliability of the GX160 engine.

Downloading the Honda GX160 Parts Manual PDF

Download the Honda GX160 parts manual PDF from official Honda websites or authorized dealers. Ensure authenticity by verifying sources to avoid counterfeit documents and ensure safety.

Steps to Find and Download the Manual

To find and download the Honda GX160 parts manual PDF, visit the official Honda website or authorized dealers. Use the search bar with the model number “GX160” to locate the manual. Ensure the source is authentic to avoid counterfeit documents. Some websites may require creating an account or verifying ownership. Once found, click the download link and save the PDF to your device for easy access. Always verify the manual’s relevance to your engine model before use to ensure accuracy and safety.

Verification of the Manual’s Authenticity and Relevance

Ensure the manual is authentic by downloading it from Honda’s official website or authorized dealers. Cross-reference the model number and engine specifications with your GX160 to confirm relevance. Look for Honda’s official branding, detailed diagrams, and clear instructions. Avoid manuals from unverified sources, as they may contain inaccurate information. Verify the publication date and version to match your engine’s production year. Using an authentic and relevant manual ensures safety, accuracy, and compliance with manufacturer guidelines, preventing potential damage or misuse of your engine.

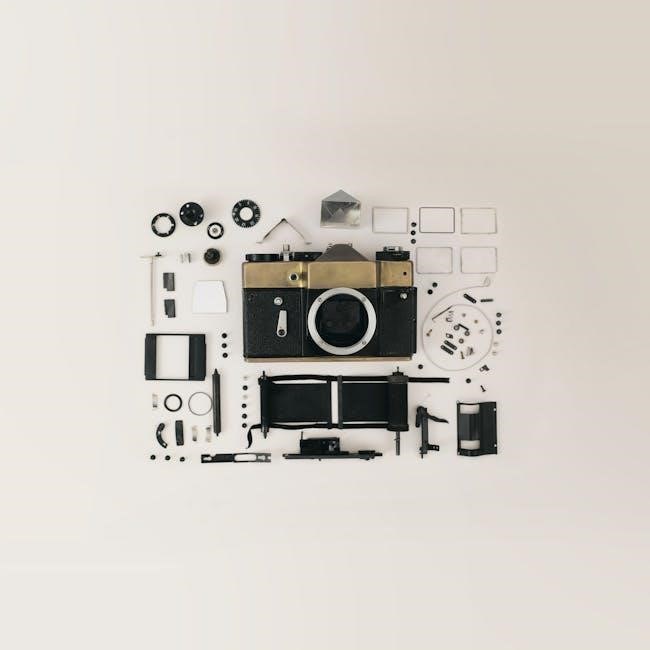

Understanding the Parts Diagram

The parts diagram in the Honda GX160 manual provides a visual breakdown of the engine’s components, enabling users to identify and locate parts accurately for maintenance and repair;

Key Components and Their Functions

The Honda GX160 engine consists of essential components like the cylinder head, carburetor, crankshaft, and camshaft, which work together to ensure efficient combustion and power generation. The governor regulates engine speed, while the air filter and muffler manage airflow and noise reduction. The fuel tank stores the necessary fuel, and the oil system lubricates moving parts to prevent wear. Understanding these components is crucial for effective maintenance and repair, as outlined in the parts manual.

How to Identify Parts Using the Diagram

To identify parts using the diagram in the Honda GX160 parts manual, locate the visual representation of the engine. Each component is labeled with a number or letter, corresponding to a detailed list. Cross-reference these labels with the parts list to match numbers with names. Key components like the cylinder head, crankshaft, or carburetor are clearly marked. Use the index or search function to quickly find specific parts. This method ensures accurate identification for maintenance or repair tasks, helping you understand the engine’s structure and functionality.

Maintenance and Repair Guidelines

Regular maintenance is crucial for the Honda GX160 engine’s durability. Follow the manual’s routine procedures, such as oil changes and air filter cleaning, to ensure optimal performance. Address common issues promptly using the diagnostic guides provided. Advanced repair techniques are also outlined for complex problems, ensuring comprehensive care for your engine.

Routine Maintenance Procedures

Regular maintenance ensures the Honda GX160 engine runs smoothly. Change the engine oil every 50 hours of operation, using the recommended viscosity for your climate. Clean or replace the air filter as needed to maintain proper airflow. Inspect and gap the spark plug periodically to ensure ignition efficiency. Check the fuel filter and replace it annually or if contamination is suspected. Refer to the parts manual for specific procedures and intervals to keep your engine in optimal condition and prevent premature wear.

Advanced Repair Techniques for Common Issues

For complex issues, the GX160 manual offers detailed repair guidance. If the engine overheats, inspect the cylinder head for warping and replace the gasket if necessary. Address low power output by checking the carburetor for blockages or improper adjustments. Replacing worn piston rings or valves can resolve excessive oil consumption. Utilize the parts diagram to identify components needing replacement. Always follow torque specifications and reassembly procedures to ensure reliability. These advanced techniques help restore performance and extend the engine’s lifespan, as outlined in the manual. Regularly referencing the guide prevents recurring problems and ensures durability.

Troubleshooting Common Problems

Identify engine malfunction symptoms such as rough running or low power. Use the manual to diagnose issues like faulty spark plugs or clogged air filters. Troubleshoot efficiently by following step-by-step guides to resolve common problems and restore optimal performance. Regular checks and timely repairs ensure smooth operation and extend engine lifespan, as detailed in the manual.

Identifying Symptoms of Engine Malfunction

Recognize engine issues like excessive vibration, unusual noises, or overheating. Look for signs such as decreased performance, rough idling, or difficulty starting. The manual helps identify these symptoms, linking them to potential problems like faulty spark plugs, clogged air filters, or improper fuel flow. By referencing the parts diagram, users can pinpoint components needing inspection or replacement. Early detection of these symptoms ensures timely repairs, preventing further damage and maintaining engine reliability. Regular checks as outlined in the manual are crucial for proactive maintenance.

Diagnosing Issues Using the Manual

Use the Honda GX160 parts manual to systematically diagnose engine problems. Refer to the troubleshooting section for symptom-to-cause analysis. Cross-reference parts diagrams to locate components and verify connections. For example, voltage issues can be traced to faulty regulators, while excessive oil consumption may indicate worn piston rings. The manual provides step-by-step inspection procedures and repair guidance, ensuring accurate diagnosis and effective resolution. By following these guidelines, users can efficiently identify and address malfunctions, minimizing downtime and extending engine lifespan.

Adjusting the Governor for Optimal Performance

Adjusting the governor ensures optimal engine performance and safe operation. The manual provides detailed steps to fine-tune the governor settings for desired RPM and efficiency.

Understanding Governor Settings

The governor on the Honda GX160 regulates engine speed, ensuring it operates within a safe RPM range. Proper settings maintain consistent power output and prevent over-revving, which can damage the engine. The governor system includes a spring and an arm that control throttle opening based on load. Adjusting these components allows customization of engine performance for specific applications like go-karts or generators. Understanding how these settings interact is crucial for optimal engine operation and longevity.

Step-by-Step Guide to Adjusting the Governor

To adjust the governor on your Honda GX160, start by loosening the governor arm at the governor shaft. Move the arm away from the carburetor as far as possible. Next, adjust the spring tension by turning the adjustment screw clockwise or counterclockwise to achieve the desired RPM. After making adjustments, tighten the governor arm to secure the new setting. Always test the engine afterward to ensure proper operation. Refer to the manual for specific instructions and safety precautions to avoid engine damage or unsafe conditions.

Safety Precautions and Best Practices

Always wear protective gear, including gloves and goggles, when working with the engine. Ensure proper ventilation to avoid carbon monoxide exposure and follow manual guidelines to prevent damage. Use genuine Honda parts for reliability and safety, adhering to operational instructions for optimal performance and longevity. Regular maintenance is essential to ensure the engine operates safely and efficiently. Properly dispose of waste materials and follow environmental regulations. Keep the work area clean and well-lit to minimize risks and ensure a safe working environment. Never operate the engine near open flames or sparks, and always turn it off before performing repairs. Use the correct tools to avoid damaging components and ensure all adjustments are made according to the manual. Follow all safety warnings and precautions outlined in the manual to prevent accidents and maintain the engine’s performance. Keep children and pets away from the engine while it is in operation. Regularly inspect the engine and its components for signs of wear or damage and address any issues promptly. Use the correct fuel and oil specifications to prevent engine damage and ensure proper lubrication. Avoid overloading the engine or operating it at extreme temperatures to maintain its longevity. Keep a fire extinguisher nearby and ensure it is easily accessible in case of emergencies. Use the engine only for its intended purposes and follow all local safety regulations. Properly store the engine and its components when not in use to prevent theft or damage. Regularly check and maintain the air filter to ensure proper airflow and engine performance. Use the correct procedure for starting and stopping the engine to prevent sudden surges or stalls. Never tamper with safety devices or bypass safety features, as this can lead to serious injury or engine failure. Always follow the manufacturer’s recommendations for maintenance and repair to ensure the engine operates safely and efficiently. Keep a copy of the manual nearby for quick reference during repairs or maintenance. Use the correct torque specifications when tightening bolts and nuts to prevent damage to threads or components. Regularly check the fuel line and connections for leaks or damage to prevent fires or fuel spills. Use the correct procedure for handling and storing fuel to prevent accidents and environmental contamination. Always disconnect the spark plug wire before performing any repairs to prevent accidental engine start-up. Use the correct tools and techniques when working with small parts to avoid losing or damaging them. Regularly inspect the exhaust system for leaks or damage to prevent carbon monoxide poisoning. Use the correct procedure for disposing of used oil and filters to protect the environment. Always follow the manufacturer’s guidelines for breaking in a new engine to ensure proper wear-in of moving parts. Use the correct procedure for cleaning the engine and its components to prevent damage from dirt or debris. Regularly check the battery terminals for corrosion or damage and clean them as needed to ensure proper electrical connections. Use the correct procedure for handling and storing the engine during the off-season to prevent rust or corrosion. Always follow the manufacturer’s recommendations for winterizing the engine to ensure it starts reliably in cold weather. Keep a record of all maintenance and repairs to track the engine’s history and ensure it remains in good condition. Use the correct procedure for synchronizing multiple engines or equipment to ensure proper operation and prevent damage. Regularly check the engine’s mounts and vibration dampeners for wear or damage to prevent excessive vibration or noise. Use the correct procedure for adjusting the valve clearance to ensure proper engine performance and prevent damage to valves or cylinder head. Always follow the manufacturer’s guidelines for towing or transporting the engine to prevent damage or instability. Use the correct procedure for handling and storing the engine’s components when they are removed for repairs to prevent loss or damage. Regularly inspect the engine’s cooling system for leaks or damage to prevent overheating and ensure proper temperature regulation. Use the correct procedure for bleeding the fuel system after repairs to prevent air pockets and ensure proper fuel flow. Always follow the manufacturer’s recommendations for selecting and installing accessories to ensure compatibility and proper operation. Use the correct procedure for handling and disposing of hazardous materials to protect the environment and prevent health risks. Regularly check the engine’s electrical system for worn or damaged wires, connectors, or spark plugs to ensure proper ignition and prevent misfires. Use the correct procedure for diagnosing and repairing electrical faults to prevent further damage or safety hazards. Always follow the manufacturer’s guidelines for updating or modifying the engine to ensure compliance with safety standards and regulations. Use the correct procedure for calibrating or adjusting engine components to ensure proper performance and prevent operational issues. Regularly inspect the engine’s belts and hoses for signs of wear or damage and replace them as needed to prevent unexpected failures. Use the correct procedure for handling and storing the engine’s belts and hoses to prevent damage from heat, chemicals, or UV exposure. Always follow the manufacturer’s recommendations for selecting and using aftermarket parts to ensure compatibility and maintain engine performance. Use the correct procedure for documenting and reporting any issues or defects to the manufacturer to ensure proper resolution and maintain warranty coverage. Regularly check the engine’s emission control systems for proper function and adjust or replace components as needed to comply with environmental regulations. Use the correct procedure for handling and disposing of emissions-related components to prevent environmental contamination. Always follow the manufacturer’s guidelines for preparing the engine for storage or long-term inactivity to prevent rust or corrosion. Use the correct procedure for handling and storing the engine’s fuel system components to prevent contamination or degradation. Regularly inspect the engine’s throttle and choke mechanisms for proper function and adjust or clean them as needed to ensure smooth operation. Use the correct procedure for handling and repairing the engine’s throttle and choke components to prevent damage or malfunction. Always follow the manufacturer’s recommendations for selecting and using fuel additives or cleaners to ensure compatibility and prevent engine damage. Use the correct procedure for handling and storing the engine’s lubricants and fluids to prevent contamination or degradation. Regularly check the engine’s drain plugs and filters for proper installation and condition to ensure they are functioning correctly. Use the correct procedure for handling and disposing of used filters and drain plugs to prevent environmental contamination. Always follow the manufacturer’s guidelines for updating or modifying the engine’s software or electronic systems to ensure compatibility and proper operation. Use the correct procedure for diagnosing and repairing electronic system faults to prevent further damage or safety hazards. Regularly inspect the engine’s wiring harness and connectors for wear or damage and repair or replace them as needed to ensure proper function. Use the correct procedure for handling and storing the engine’s electrical components to prevent damage from moisture, heat, or vibration. Always follow the manufacturer’s recommendations for selecting and installing electrical accessories to ensure compatibility and prevent malfunctions. Use the correct procedure for calibrating or adjusting engine settings after repairs to ensure proper performance and efficiency. Regularly check the engine’s air filter and intake system for cleanliness and proper function to ensure adequate airflow and prevent overheating. Use the correct procedure for cleaning or replacing the air filter to maintain optimal engine performance and fuel efficiency. Always follow the manufacturer’s guidelines for selecting and using air filter cleaners or oils to ensure compatibility and prevent damage. Use the correct procedure for handling and storing the engine’s intake components to prevent damage from dirt, moisture, or pests. Regularly inspect the engine’s muffler and exhaust system for leaks or damage to prevent noise pollution and ensure proper emission control. Use the correct procedure for repairing or replacing muffler and exhaust components to prevent environmental contamination and maintain performance. Always follow the manufacturer’s recommendations for selecting and installing exhaust system accessories to ensure compatibility and compliance with regulations. Use the correct procedure for handling and storing the engine’s exhaust components to prevent damage from heat, rust, or corrosion. Regularly check the engine’s fuel tank and lines for leaks or damage to prevent fuel spills or fires. Use the correct procedure for repairing or replacing fuel tank and line components to ensure proper sealing and prevent leaks. Always follow the manufacturer’s guidelines for selecting and using fuel additives or treatments to ensure compatibility and prevent corrosion. Use the correct procedure for handling and storing the engine’s fuel system components to prevent contamination or degradation. Regularly inspect the engine’s ignition system for proper function and replace spark plugs or ignition coils as needed to ensure efficient combustion. Use the correct procedure for handling and storing the engine’s ignition components to prevent damage from moisture, heat, or vibration. Always follow the manufacturer’s recommendations for selecting and using ignition system accessories to ensure compatibility and proper operation. Use the correct procedure for diagnosing and repairing ignition system faults to prevent further damage or safety hazards. Regularly check the engine’s cooling system for proper function and adjust or replace components as needed to prevent overheating. Use the correct procedure for handling and storing the engine’s cooling system components to prevent damage from corrosion, scale, or contamination. Always follow the manufacturer’s guidelines for selecting and using cooling system additives or treatments to ensure compatibility and prevent damage. Use the correct procedure for handling and disposing of used cooling fluids to prevent environmental contamination. Regularly inspect the engine’s lubrication system for

Essential Safety Measures When Working with the Engine

Always wear protective gear, including gloves and goggles, when handling the Honda GX160 engine. Ensure proper ventilation to avoid carbon monoxide exposure. Follow the manual’s guidelines to prevent damage and ensure safety. Use genuine Honda parts for reliability and adhere to operational instructions. Regular maintenance is crucial for safe operation. Dispose of waste materials properly and follow environmental regulations. Keep the workspace clean and well-lit to minimize risks. Avoid open flames or sparks near the engine and turn it off before repairs. Use correct tools to prevent component damage and follow all safety warnings in the manual.